The lifecycle of an LVL product

Posted: August 6th, 2020

LVLs start their life just as any timber product does, as a tree in a vast timber forest. The unique manufacturing process used to create LVLs means that when a tree deemed worthy to be an LVL, it is in for a wild ride.

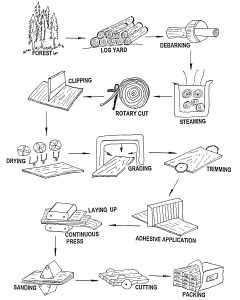

From the beginning, a tree follows a path similar to those destined for regular timber. The tree is cut, transported and made ready for manufacturing. It’s at the manufacturing stage where LVLs differ from regular timber. The initial steps for a tree to become an LVL start with debarking the log. Once the bark has been removed the log is then peeled with a special technique called a rotary cut using a lathe. This unravels the log around its circumference following its growth rings which yields large, thin sheets of timber.

From the beginning, a tree follows a path similar to those destined for regular timber. The tree is cut, transported and made ready for manufacturing. It’s at the manufacturing stage where LVLs differ from regular timber. The initial steps for a tree to become an LVL start with debarking the log. Once the bark has been removed the log is then peeled with a special technique called a rotary cut using a lathe. This unravels the log around its circumference following its growth rings which yields large, thin sheets of timber.

These sheets of timber called Veneers are clipped to more manageable sizes, dried using hot air blown out of powerful jets and then graded to ensure each veneer meets LVL standards. This process is quite similar to plywood manufacturing. However, one of the major differences being how the wood grains are orientated. LVLs are lined up so almost all of the veneer grains are lined up along the length of the timber.

After being trimmed, any imperfections are tidied up and the veneers are covered in an adhesive. Usually, phenol-formaldehyde glue. Which is waterproof and sets very rigidly. The veneers are then layered and pressed together with a lot of pressure and heat. This is done by a press line. A long continuous press that enables virtually any length of LVL to be produced.

When the LVL is pressed some final touches like sanding are made to the timber board before it is cut into individual lengths of LVL. From there the LVLs are bundled and packaged and made ready to transport.

The manufacturing process is an important part of an LVLs lifecycle. But the most exciting part is where it ends up next. The versatility and strength of LVLs mean that they can be used almost anywhere! From housing frames, ceiling and flooring joists to architectural roof truss, LVLs come in all shapes and sizes for whatever you are looking for.

To read more on LVL products head to What makes LVL products so great.